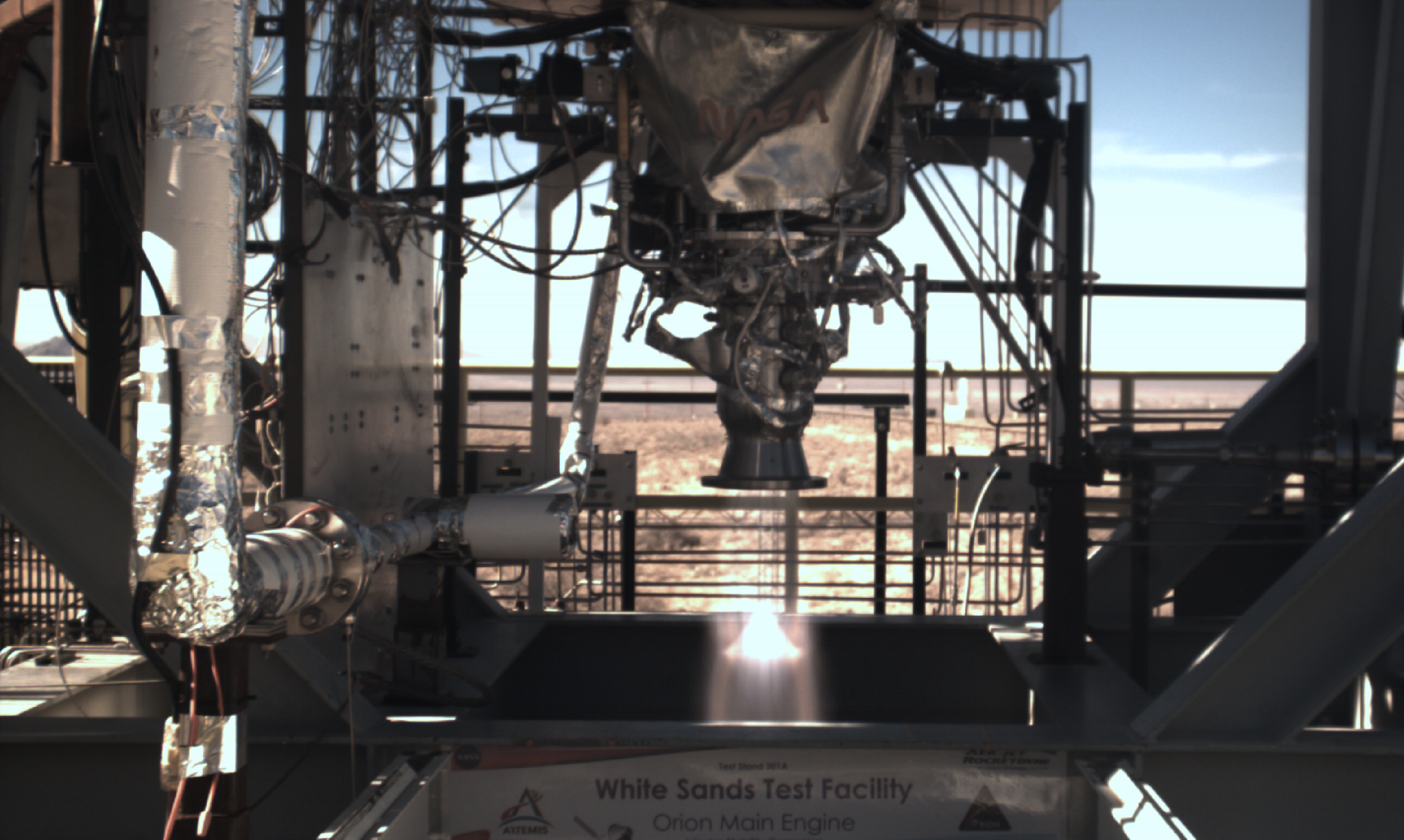

White Sands Propulsion Team Tests 3D-Printed Orion Engine Component

When the Orion spacecraft carries the first Artemis crews to the Moon and back, it will rely on the European Service Module contributed by ESA (European Space Agency) to make the journey. The service module provides electrical power generation, propulsion, temperature control, and consumable storage for Orion, up to the moment it separates from the […]

When the Orion spacecraft carries the first Artemis crews to the Moon and back, it will rely on the European Service Module contributed by ESA (European Space Agency) to make the journey. The service module provides electrical power generation, propulsion, temperature control, and consumable storage for Orion, up to the moment it separates from the crew module prior to re-entry into Earth’s atmosphere.

For the first six Artemis missions – Artemis I through Artemis VI – NASA and ESA will use a refurbished Orbital Maneuvering System (OMS) engine from the space shuttle program as the European Service Module’s main engine. Beyond Artemis VI, NASA will need a new engine to support Orion.

That need will be met by the Orion Main Engine (OME) in development with Aerojet Rocketdyne (now L3 Harris), but before the OME can fly, all of its components must be thoroughly tested.

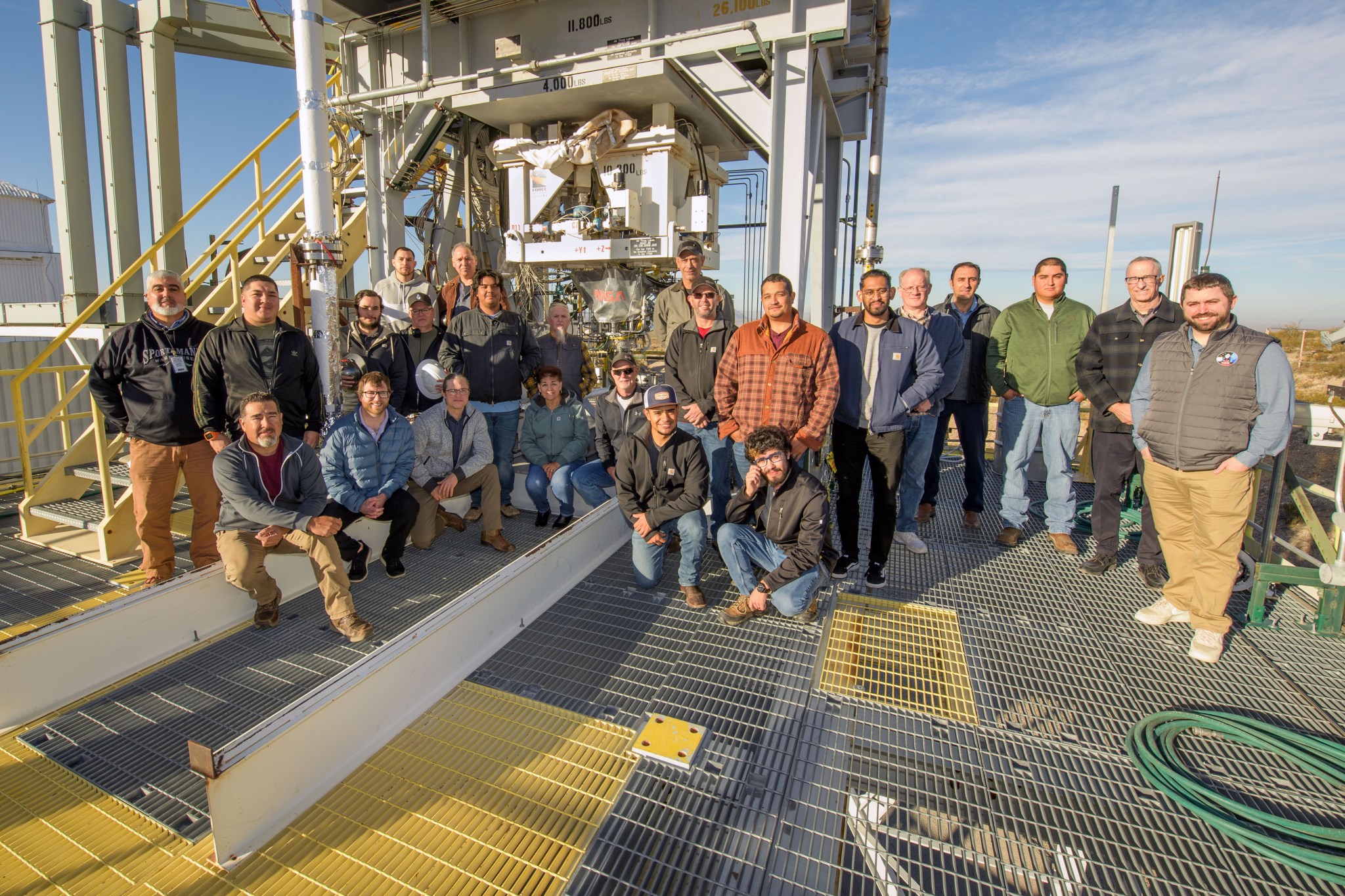

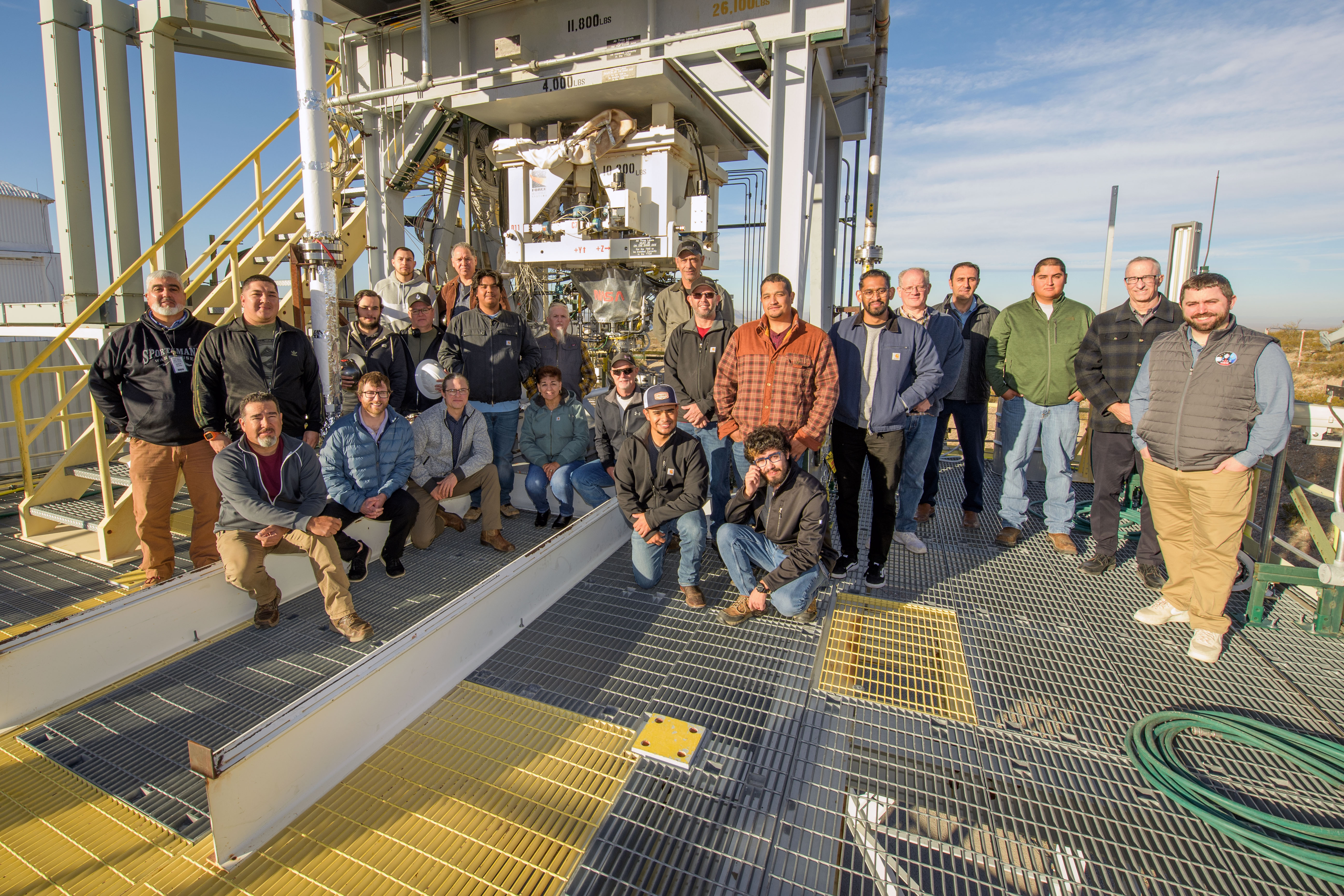

Enter the Propulsion Test Office at NASA’s White Sands Test Facility. From November 2023 to January 2024, this team led rigorous testing of a critical OME component: the injector that delivers propellants to power the engine and provides the thrust necessary to return Orion home from the Moon.

The tests were performed on Test Stand 301A in White Sands’ Propulsion 300 Area. The injector was mounted to a test engine that fired multiple times for three seconds each, for a total of 21 tests. With each test, the White Sands team sought to demonstrate the OME injector’s ability to maintain consistent and controlled combustion and to return to normal operations if the combustion process was artificially perturbed.

Many White Sands team members were involved in this effort. James Hess, project manager and operations director, ensured the tests were completed safely and successfully by overseeing operations, and confirming test requirements were met. James Mahoney handled the test schedule and budget as project lead, while Jordan Aday directed operations and the actual tests. Other key roles included lead electrical engineer Sal Muniz, and instrumentation engineer Jesus Lujan-Martino. Aerojet Rocketdyne’s Shaun DeSouza served as test article director, working to ensure the injector operated as expected and that test condition requirements were met. Additional support was provided by OME Program team members at NASA’s Johnson Space Center and Glenn Research Center.

The results confirmed that the OME injector could maintain stable combustion, and the team determined the tests were successful. A unique aspect of the OME injector is that it was fabricated through an additive manufacturing process called selective laser machining – basically 3D printing with metallic powders instead of plastics. Demonstrating the effectiveness of 3D printed components could help NASA and its partners lower costs and increase efficiencies in development processes.

The injector design will now be incorporated into a full OME that will be tested as a full engine assembly at White Sands once it is ready.

What's Your Reaction?

.jpg?#)