The Marshall Star for July 10, 2024

NASA Moon Rocket Stage for Artemis II Moved, Prepped for Shipment NASA is preparing the SLS (Space Launch System) rocket core stage that will help power the first crewed mission of NASA’s Artemis campaign for shipment. On July 6, NASA and Boeing, the core stage lead contractor, moved the Artemis II rocket stage to another part of […]

The Marshall Star for July 10, 2024

NASA Moon Rocket Stage for Artemis II Moved, Prepped for Shipment

NASA is preparing the SLS (Space Launch System) rocket core stage that will help power the first crewed mission of NASA’s Artemis campaign for shipment. On July 6, NASA and Boeing, the core stage lead contractor, moved the Artemis II rocket stage to another part of the agency’s Michoud Assembly Facility. The move comes as teams prepare to roll the massive rocket stage to the agency’s Pegasus barge for delivery to NASA’s Kennedy Space Center in mid-July.

Prior to the move, technicians began removing external access stands, or scaffolding, surrounding the rocket stage in early June. NASA and Boeing teams used the scaffolding surrounding the core stage to assess the interior elements, including its complex avionics and propulsion systems. The 212-foot core stage has two huge propellant tanks, avionics and flight computer systems, and four RS-25 engines, which together enable the stage to operate during launch and flight.

The stage is fully manufactured and assembled at Michoud. Building, assembling, and transporting is a joint process for NASA, Boeing, and lead RS-25 engines contractor Aerojet Rocketdyne, an L3Harris Technologies company.

NASA is working to land the first woman, first person of color, and its first international partner astronaut on the Moon under Artemis. SLS is part of NASA’s backbone for deep space exploration, along with the Orion spacecraft, supporting ground systems, advanced spacesuits and rovers, the Gateway in orbit around the Moon, and commercial human landing systems. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single launch.

NASA’s Marshall Space Flight Center manages the SLS Program and Michoud.

Marshall Researchers Battle Biofilm in Space

By Rick Smith

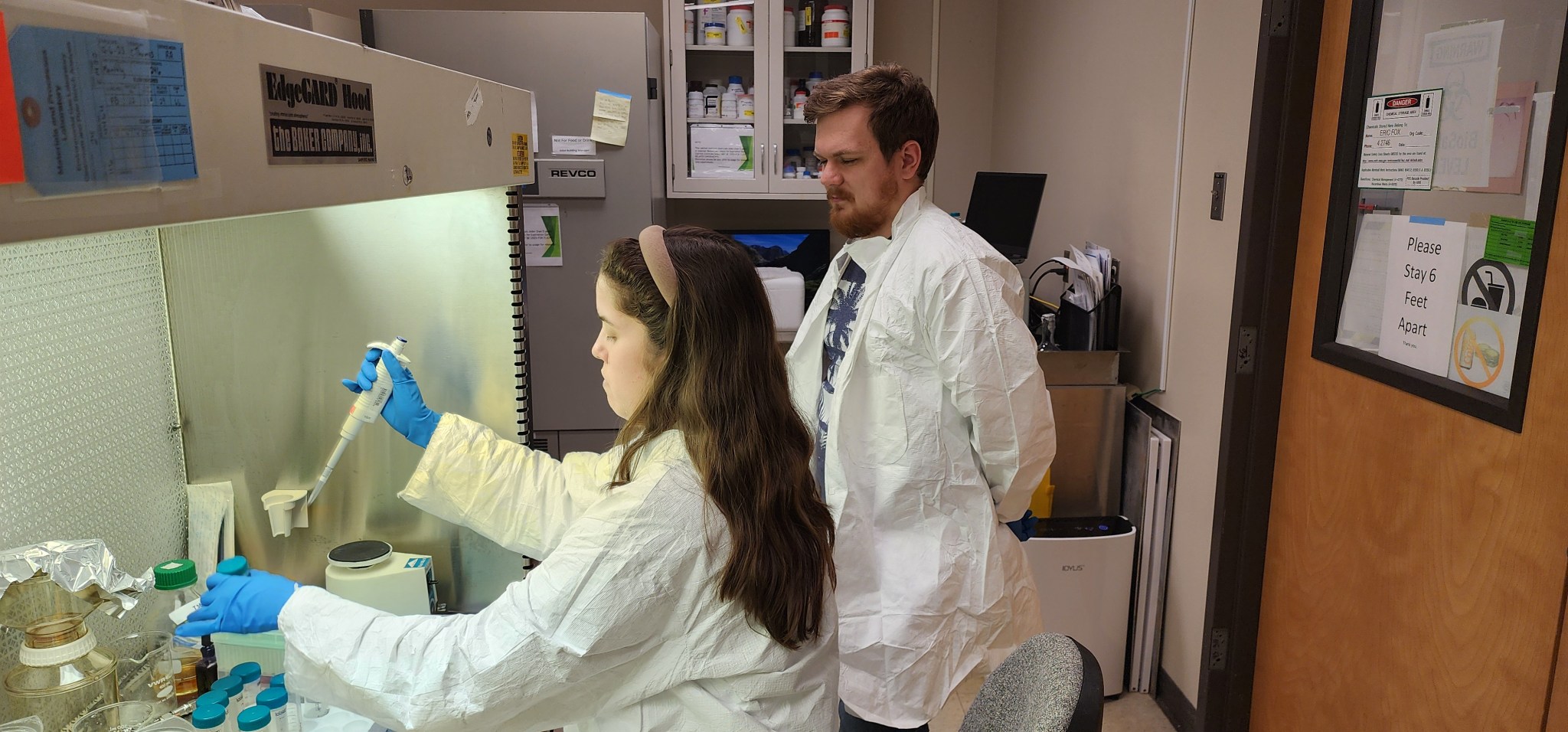

A small group of scientists on the biofilm mitigation team at NASA’s Marshall Space Center study solutions to combat fast-growing colonies of bacteria or fungi, known as biofilm, for future space missions.

Biofilm occurs when a cluster of bacteria or fungi generates a slimy matrix of “extracellular polymeric substances” to protect itself from adverse environmental factors. Biofilm can be found nearly anywhere, from the gray-green scum floating on stagnant pond water to the pinkish ring of residue in a dirty bathtub.

For medical, food production, and wastewater processing industries, biofilm is often a costly issue. But offworld, biofilm proves to be even more resilient.

“Bacteria shrug off many of the challenges humans deal with in space, including microgravity, pressure changes, ultraviolet light, nutrient levels, even radiation,” said Yo-Ann Velez-Justiniano, a Marshall microbiologist and environmental control systems engineer.

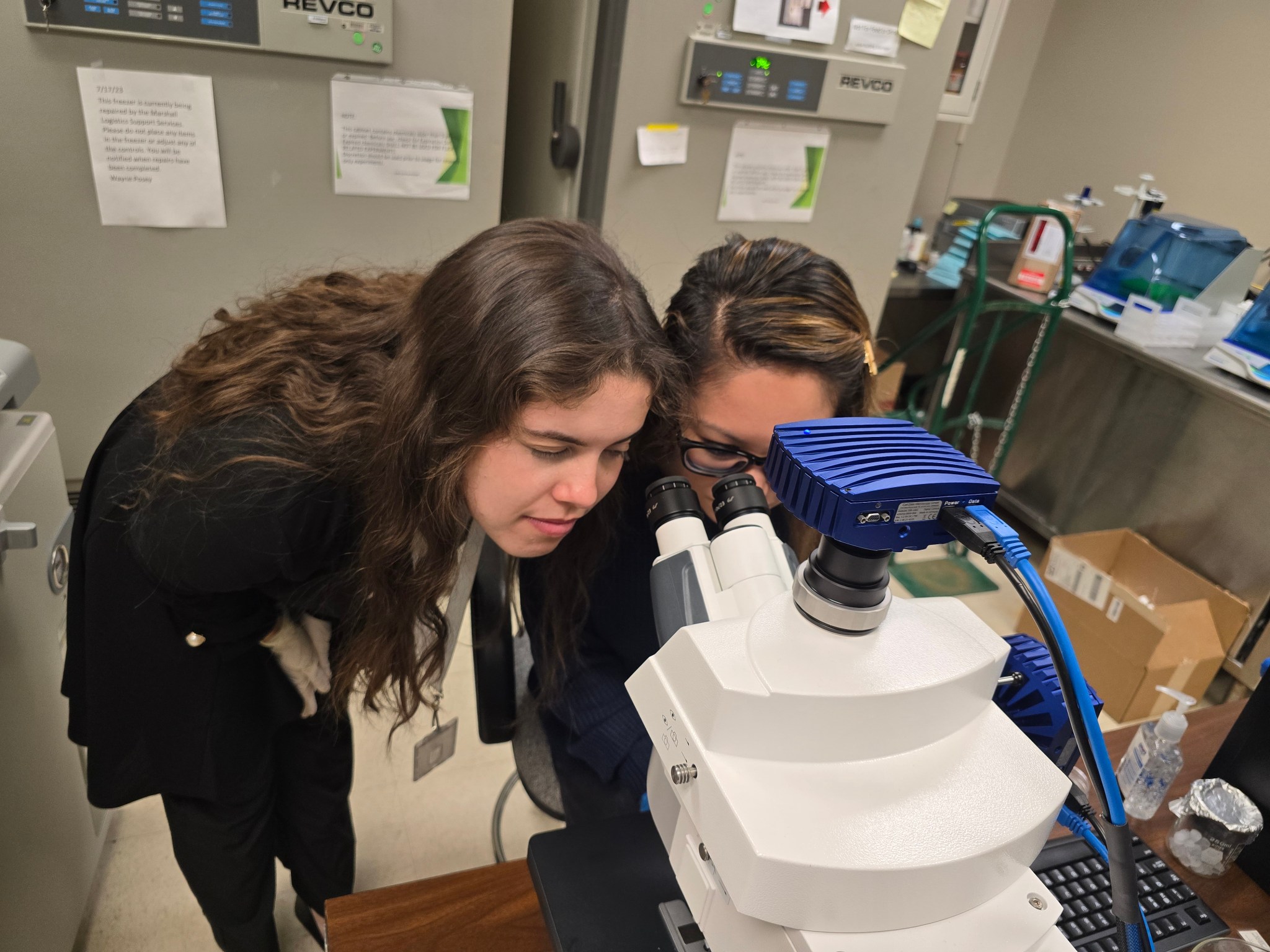

“Biofilm is icky, sticky – and hard to kill,” said Liezel Koellner, a chemical engineer and NASA Pathways intern from North Carolina State University in Raleigh. Koellner used sophisticated epifluorescence microscopy, 3D visualizations of 2D images captured at different focal planes, to fine-tune the team’s studies.

Keenly aware of the potential hurdles biofilm could pose in future Artemis-era spacecraft and lunar habitats, NASA tasked engineers and chemists at Marshall to study mitigation techniques. Marshall built and maintains the International Space Station’s ECLSS (Environment Control and Life Support System) and is developing next-generation air and water reclamation and recycling technologies, including the system’s wastewater tank assembly.

“The wastewater tank is ‘upstream’ from most of our built-in water purification methods. Because it’s a wastewater feed tank, bacteria and fungus grow well there, generating enough biofilm to clog flow paths and pipes along the route,” said Eric Beitle, ECLSS test engineer at Marshall.

To date, the solution has been to pull and replace old hardware once parts become choked with biofilm. But engineers want to avoid the need for such tactics.

“Even with the ability to 3D-print spare parts on the Moon or Mars, it makes sense to find strategies that prevent biofilm buildup in the first place,” said Velez-Justiniano.

The team took the first step in June 2023 by publishing the complete genome sequence of several strains of bacteria isolated from the space station’s water reclamation system, all of which cultivate biofilm formation.

They next designed a test stand simulating conditions in the wastewater tank about 250 miles overhead, which permits simultaneous study of multiple mitigation options. The rig housed eight Centers for Disease Control and Prevention biofilm reactors – cylindrical devices roughly the size of a runner’s water bottle – each 1/60th the size of the actual tank.

Each bioreactor holds up to 21 unique test samples on slides, bathed continuously in a flow of real or ersatz wastewater, timed and measured by the automated system, and closely monitored by the team. Because of the compact bioreactor size, the test stand required 2.1 gallons of ersatz flow per week, continuously trickling 0.1 milliliters per minute into each of the eight bioreactors.

“Essentially, we built a collection of tiny systems that all had to permit minute changes to temperature and pressure, maintain a sterile environment, provide autoclave functionality, and run in harmony for weeks at a time with minimal human intervention,” Beitle said. “One phase of the test series ran nonstop for 65 days, and another lasted 77 days. It was a unique challenge from an engineering perspective.”

Different surface mitigation strategies, upstream counteragents, antimicrobial coatings, and temperature levels were introduced in each bioreactor. One promising test involved duckweed, a plant already recognized as a natural water purification system and for its ability to capture toxins and control wastewater odor. By devouring nutrients upstream of the bioreactor, the duckweed denied the bacteria what it needs to thrive, reducing biofilm growth by up to 99.9%.

Over the course of the three-month testing period, teams removed samples from each bioreactor at regular intervals and prepared for study under a microscope to make a detailed count of the biofilm colony-forming units on each plate.

“Bacteria and fungi are smart,” Velez-Justiniano said. “They adapt. We recognize that it’s going to take a mix of effective biofilm mitigation methods to overcome this challenge.”

Biofilm poses as an obstacle to long-duration spaceflight and extended missions on other worlds where replacement parts may be costly or difficult to obtain. The biofilm mitigation team continues to assess and publish findings, alongside academic and industry partners, and will further their research with a full-scale tank experiment at Marshall. They hope to progress to flight tests, experimenting with various mitigation methods in real microgravity conditions in orbit to find solutions to keep surfaces clean, water potable, and future explorers healthy.

Smith, an Aeyon/MTS employee, supports the Marshall Office of Communications.

Pathways Intern Liezel Koellner Aids NASA Biofilm Mitigation

By Rick Smith

Liezel Koellner is a NASA Pathways intern pursuing her master’s degree in chemical engineering from North Carolina State University in Raleigh. Like most ambitious young engineers, she sought a variety of different internships to augment her classwork.

But once she got word she’d been chosen to spend the spring 2024 term conducting biochemistry experiments at NASA’s Marshall Space Flight Center, her choice was made.

“As a kid, I never imagined I could work at NASA,” she said. “It was a mind-blowing idea!”

That’s how she wound up spending the semester up to her safety gloves in bacterial goo – helping NASA’s biofilm mitigation team study strategies for vanquishing a pervasive, slimy invader playing havoc with space-based hardware. And Koellner couldn’t be happier.

Biofilm is the sticky goo generated by bacteria or fungi to armor itself against radiation, airlessness, and other conditions in space. Astronauts keep their environment fairly ship-shape – but inside closed water reclamation systems, like the one on the International Space Station, biofilm can thrive, wreaking havoc on critical life support systems.

Joining a team of Marshall microbiologists, chemists, and hardware engineers, Koellner spent weeks cultivating sample bacteria – either simulated stuff chemically created onsite or samples shipped frozen from NASA and Boeing archives. She closely monitored ongoing tests, regularly pulling samples to count biofilm colonies.

Most importantly, she oversaw the use of precision epifluorescence microscopy, which employs 3D visualizations to identify layered growth in 2D sample images. That contribution most impressed Marshall microbiologist Yo-Ann Velez-Justiniano, Koellner’s supervisor and project mentor, who said it dramatically improved data accuracy.

“Liezel was able to more accurately analyze patterns of sample growth and deliver precise quantitative data identifying biofilm progression,” Velez-Justiniano said.

A formula for success

Koellner said she’s always been driven to soak up as much practical experience as possible. She was born in Guam to Filipino parents who later emigrated to San Diego, California, to raise their family. From a young age, she took school very seriously.

“I always enjoyed chemistry, observing scientific processes and documenting the effects,” Koellner said, but she was daunted by the challenges of calculus-based physics, used to model systems where change occurs and an integral part of scientific fields serving space exploration, engineering, pharmacology, and more.

That changed when she got to the University of North Carolina in Wilmington. “Suddenly, everything clicked,” she said. “With physics, it was amazing to see how math could be applied to real-life applications.”

That practical blend of disciplines led her to consider a career in chemical engineering – using chemical processes to develop products and resources for commercial uses. After completing her bachelor’s degree in chemistry at the University of North Carolina in 2022 and spending a year as a chemist for a private lab in Wilmington, she enrolled at North Carolina State, where she expects to graduate in 2026 with a master’s in chemical engineering.

From water reclamation to air recycling

With the biofilm mitigation tests completed – but her internship continuing until August – Koellner has shifted tracks, moving from the challenges of water reclamation to oxygen recovery solutions for future space habitats and on other worlds.

She’s part of a different team of Marshall ECLSS (Environment Control and Life Support System) specialists, studying ways to recover oxygen from methane gas. That capability could support a variety of oxygen recovery and recycling systems, saving and storing breathable air instead of just jettisoning it into space along with waste gas products. Koellner will write documentation and help monitor and operate the active test stand, once again working alongside Marshall specialists from various disciplines.

She said their commitment has left a lasting impression.

“Everyone is so willing to lend their expertise to pursue work that could impact NASA missions years or even decades in the future,” she said. “The diligence and enthusiasm here are tangible things. That’s the kind of engineer – the kind of person – I want to be.”

Smith, an Aeyon/MTS employee, supports the Marshall Office of Communications.

Lisa Bates Named Director of Marshall’s Engineering Directorate

Lisa Bates has been named director of the Engineering Directorate at NASA’s Marshall Space Flight Center, effective July 14. In her new role, Bates will be responsible for the center’s largest organization, comprised of more than 2,500 civil service and contractor personnel, who design, test, evaluate, and operate flight hardware and software associated with Marshall-developed space transportation and spacecraft systems, science instruments, and payloads.

Since November 2023, Bates has served as deputy director of the Engineering Directorate. She was also previously director of Marshall’s Test Laboratory. Appointed to the position in 2021, Bates provided executive leadership for all aspects of the Laboratory, including workforce, budget, infrastructure, and operations for testing.

She joined Marshall in 2008 as the Ares I Upper Stage Thrust Vector Control lead in the Propulsion Department. Since then, she has served in positions of increasing responsibility and authority. From 2009 to 2017, she served as the first chief of the new TVC Branch, which was responsible for defining operational requirements, performing analysis, and evaluating Launch Vehicle TVC systems and TVC components.

As the Space Launch System (SLS) Program Executive from 2017 to 2018, Bates supported the NASA Deputy Associate Administrator for Exploration Systems Development as the liaison and advocate of the SLS. Upon returning to MSFC in 2018, she was selected as deputy manager of the SLS Booster Element Office. Bates also served as deputy manager of the SLS Stages Office from 2018 to 2021 where she shared the responsibilities, accountability, and authorities for all activities associated with the requirements definition, design, development, manufacturing, assembly, green run test, and delivery of the SLS Program’s Stages Element.

Prior to her NASA career, Bates worked 18 years in private industry for numerous aerospace and defense contractors, including Jacobs Engineering, Marotta Scientific Controls, United Technologies (USBI), United Defense, and Sverdrup Technologies.

Bates holds a bachelor’s degree in mechanical engineering from the University of Alabama in Huntsville. She was awarded a NASA Outstanding Leadership Medal in 2013 and 2022 and has received numerous group and individual achievement awards.

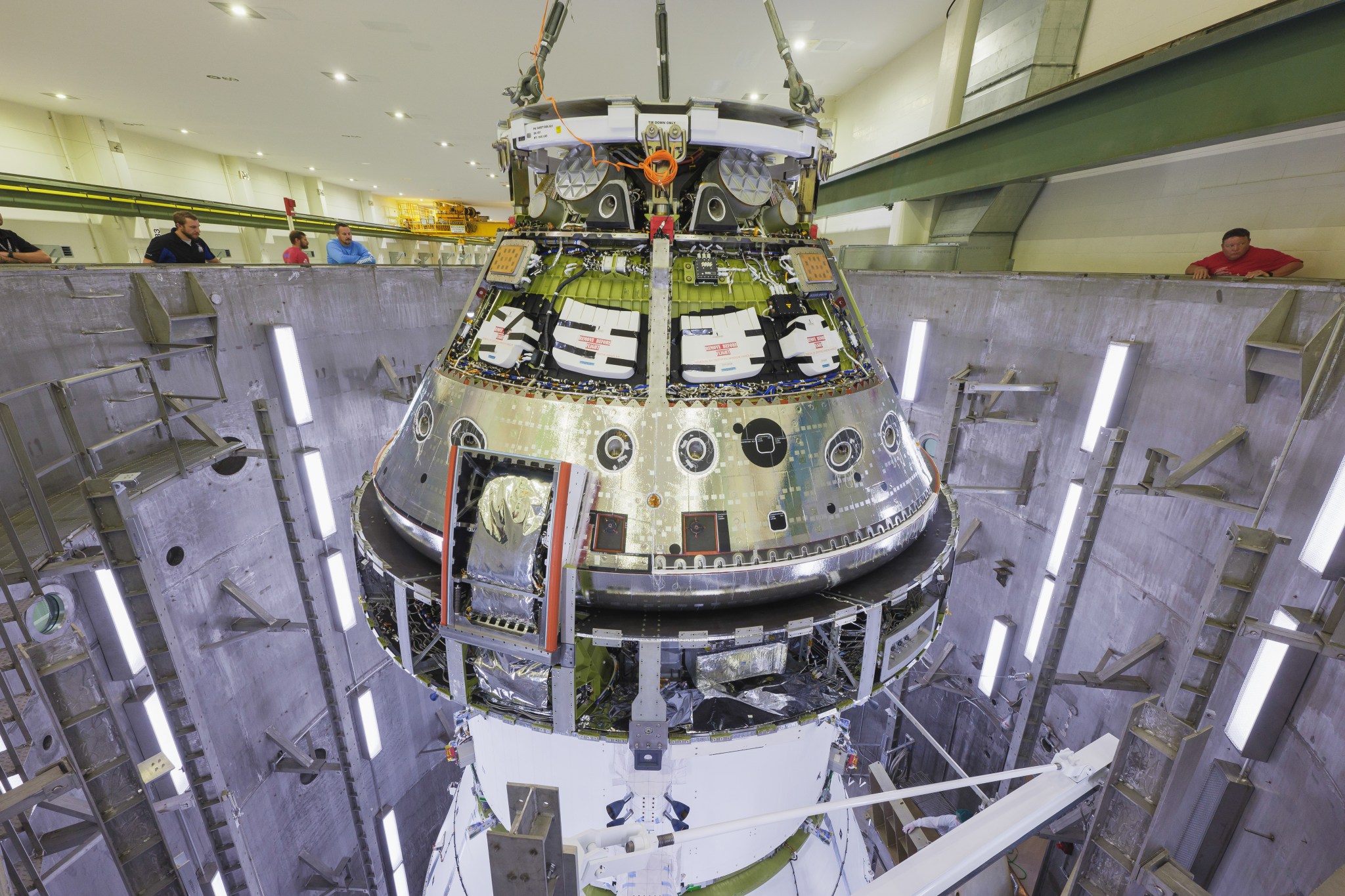

Orion on the Rise

Technicians lift NASA’s Orion spacecraft out of the Final Assembly and System Testing cell at NASA’s Kennedy Space Center on June 28. The integrated spacecraft, which will be used for the Artemis II mission to orbit the Moon, has been undergoing final rounds of testing and assembly, including end-to-end performance verification of its subsystems and checking for leaks in its propulsion systems. A 30-ton crane returned Orion into the recently renovated altitude chamber where it underwent electromagnetic testing. The spacecraft now will undergo a series of tests that will subject it to a near-vacuum environment by removing air, thus creating a space where the pressure is extremely low. This results in no atmosphere, similar to the one the spacecraft will experience during future lunar missions. The data recorded during these tests will be used to qualify the spacecraft to safely fly the Artemis II astronauts through the harsh environment of space. (NASA/Radislav Sinyak)

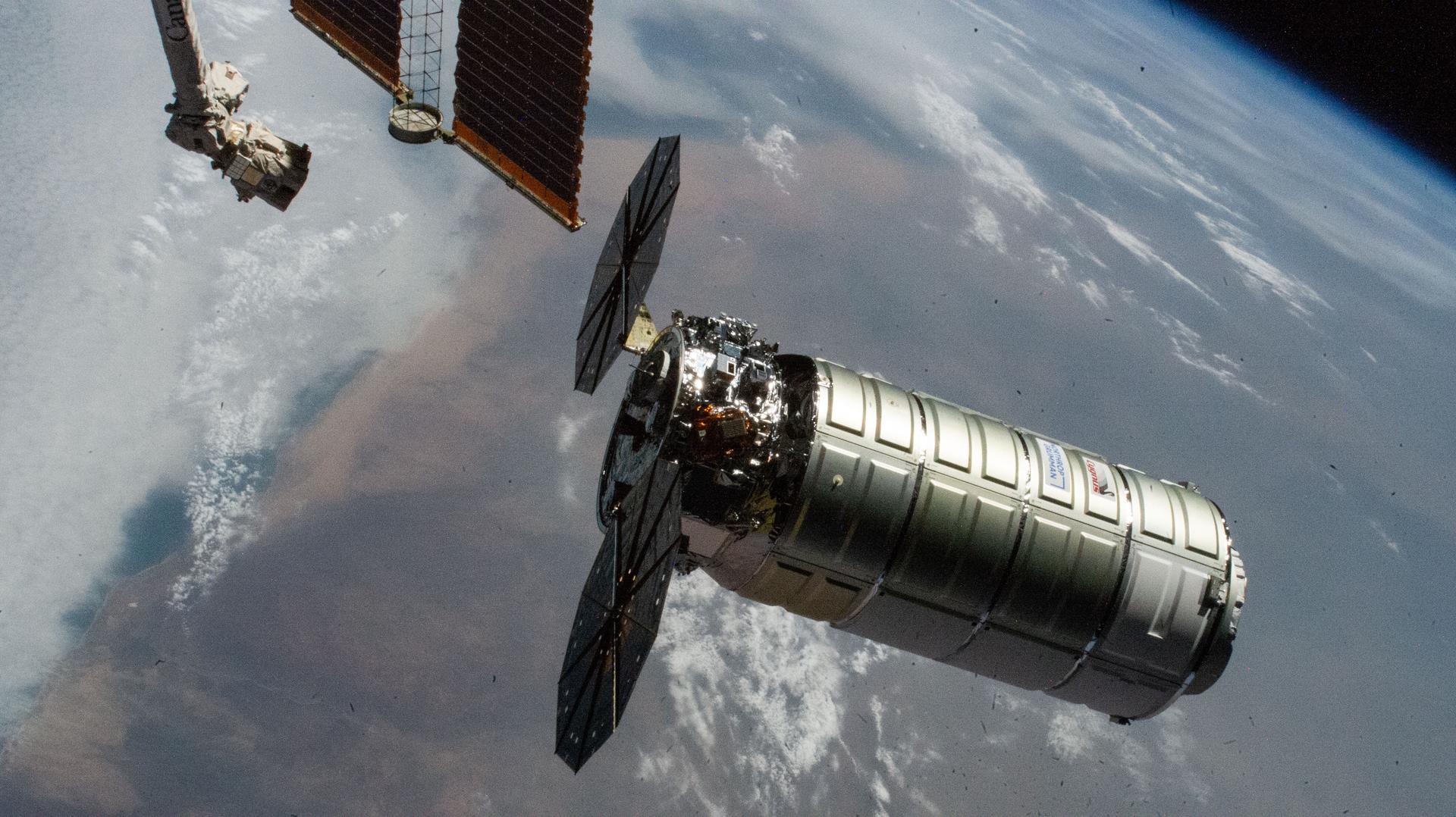

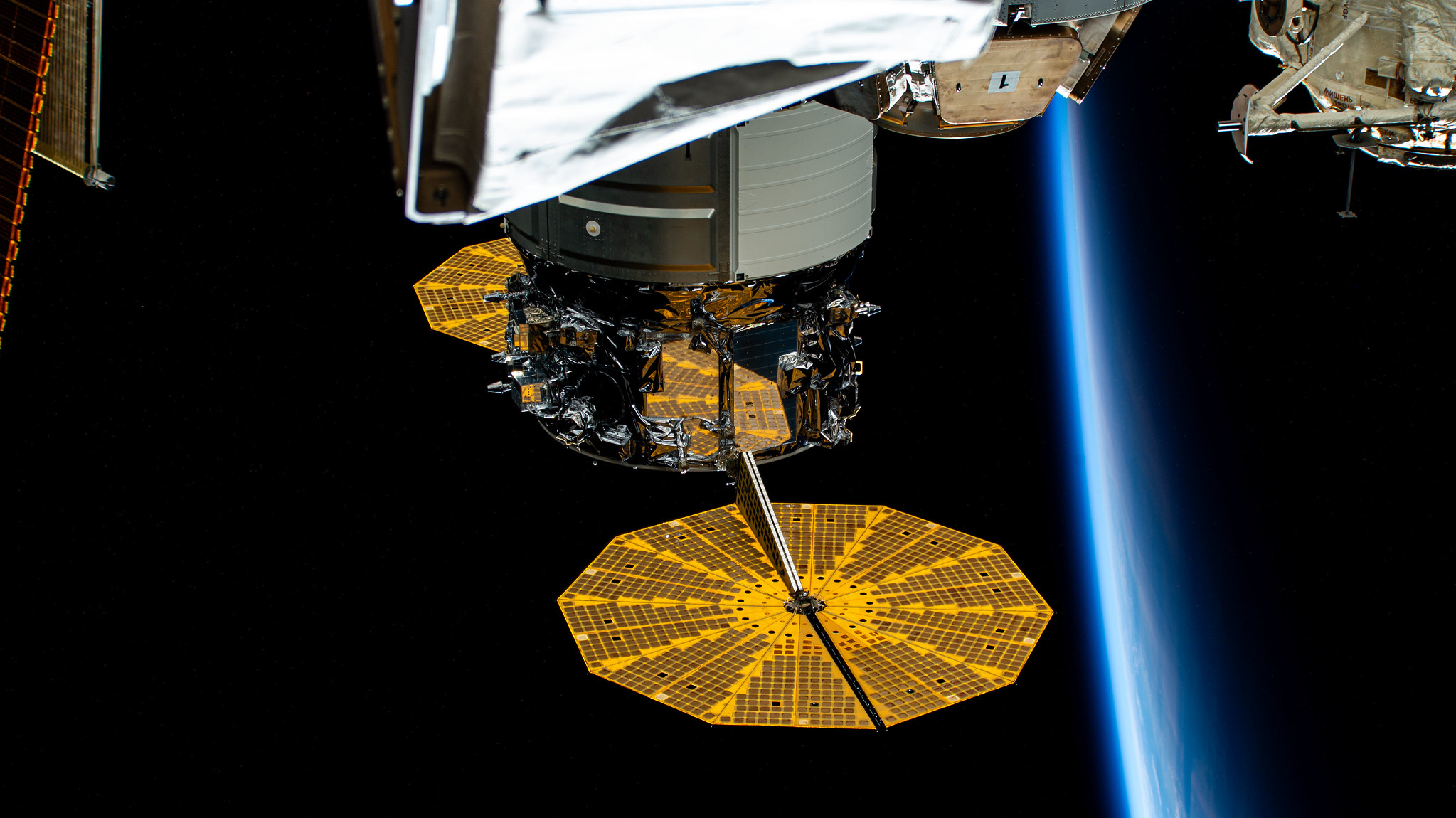

NASA to Cover Northrop Grumman’s 20th Cargo Space Station Departure

Northrop Grumman’s uncrewed Cygnus spacecraft is scheduled to depart the International Space Station on July 12, five and a half months after delivering more than 8,200 pounds of supplies, scientific investigations, commercial products, hardware, and other cargo to the orbiting laboratory for NASA and its international partners.

This mission was the company’s 20th commercial resupply mission to the space station for NASA.

Live coverage of the spacecraft’s departure will begin at 5:30 a.m. CDT on the NASA+, NASA Television, the NASA app, YouTube, and the agency’s website. Learn how to stream NASA TV through a variety of platforms including social media.

Flight controllers on the ground will send commands for the space station’s Canadarm2 robotic arm to detach Cygnus from the Unity module’s Earth-facing port, then maneuver the spacecraft into position for its release at 6 a.m. NASA astronaut Mike Barratt will monitor Cygnus’ systems upon its departure from the space station.

Following unberthing, the Kentucky Re-entry Probe Experiment-2 (KREPE-2), stowed inside Cygnus, will take measurements to demonstrate a thermal protection system for the spacecraft and its contents during re-entry in Earth’s atmosphere.

Cygnus – filled with trash packed by the station crew – will be commanded to deorbit July 13, setting up a destructive re-entry in which the spacecraft will safely burn up in Earth’s atmosphere.

The Northrop Grumman spacecraft arrived at the space station Feb. 1, following a launch on a SpaceX Falcon 9 rocket from Space Launch Complex 40 at Cape Canaveral Space Force Station.

The HOSC (Huntsville Operations Support Center) at NASA’s Marshall Space Flight Center provides engineering and mission operations support for the space station, the Commercial Crew Program, and Artemis missions, as well as science and technology demonstration missions. The Payload Operations Integration Center within the HOSC operates, plans, and coordinates the science experiments onboard the space station 365 days a year, 24 hours a day.

Get breaking news, images, and features from the space station on the station blog.

Happy Birthday, Meatball! NASA’s Iconic Logo Turns 65

On July 15, NASA’s logo is turning 65. The iconic symbol, known affectionately as “the meatball,” was developed at NASA’s Lewis Research Center (now called NASA Glenn). Employee James Modarelli, who started his career at the center as an artist and technical illustrator, was its chief designer.

The red, white, and blue design, which includes elements representing NASA’s space and aeronautics missions, became the official logo of the United States’ new space agency in 1959. A simplified version of NASA’s formal seal, the symbol has launched on rockets, flown to the Moon and beyond, and even adorns the International Space Station.

Along with its importance as a timeless symbol of exploration and discovery, the logo is also one of the world’s most recognized brand symbols. It gained its nickname in 1975 to differentiate it from NASA’s “worm” logotype. The “meatball” and these other NASA designs have made waves in pop culture.

“NASA’s brand elements are wildly popular,” said Aimee Crane, merchandising and branding clearance manager for the agency. “Every year, the agency receives requests to merchandise more than 10,000 NASA-inspired items.”

What's Your Reaction?

.jpg?#)