NASA Technology Helps Guard Against Lunar Dust

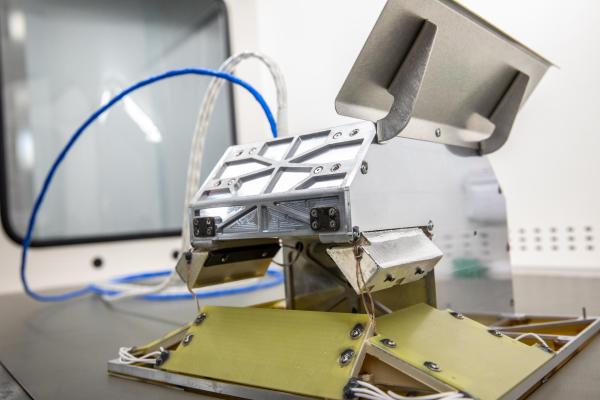

Defeating dust may be a small concern for most people on Earth, but for astronauts and spacecraft destined for the Moon or Mars, it is a significant hazard that must be mitigated. That’s why researchers at NASA’s Kennedy Space Center in Florida are seeking innovative ways to use Electrodynamic Dust Shield (EDS) technology. Using transparent […]

Defeating dust may be a small concern for most people on Earth, but for astronauts and spacecraft destined for the Moon or Mars, it is a significant hazard that must be mitigated. That’s why researchers at NASA’s Kennedy Space Center in Florida are seeking innovative ways to use Electrodynamic Dust Shield (EDS) technology.

Using transparent electrodes and electric fields, EDS technology can electrically lift and remove dust from a variety of surfaces for space applications ranging from thermal radiators, solar panels, and camera lenses to spacesuits, boots, and helmet visors. Controlling and removing the statically-charged dust will be critical to the success of Moon missions under the agency’s’ CLPS (Commercial Lunar Payload Services) initiative and Artemis campaign.

“For these CLPS and Artemis missions, dust exposure is a concern because the lunar surface is far different than what we’re used to here,” said Dr. Charles Buhler, lead research scientist at the Electrostatics and Surface Physics Laboratory at Kennedy. “Lunar regolith dust can get into gaskets and seals, into hatches, and even into habitats, which can pose a lot of issues for spacecraft and astronauts.”

Unlike dust particles on Earth, dust on the Moon’s surface is sharp and abrasive – like tiny shards of glass – because it hasn’t been exposed to weathering and elements like water and oxygen.

“Simply brushing lunar regolith across surfaces can make the problem worse because it’s also very electrostatically charged and highly insulating,” Buhler said.

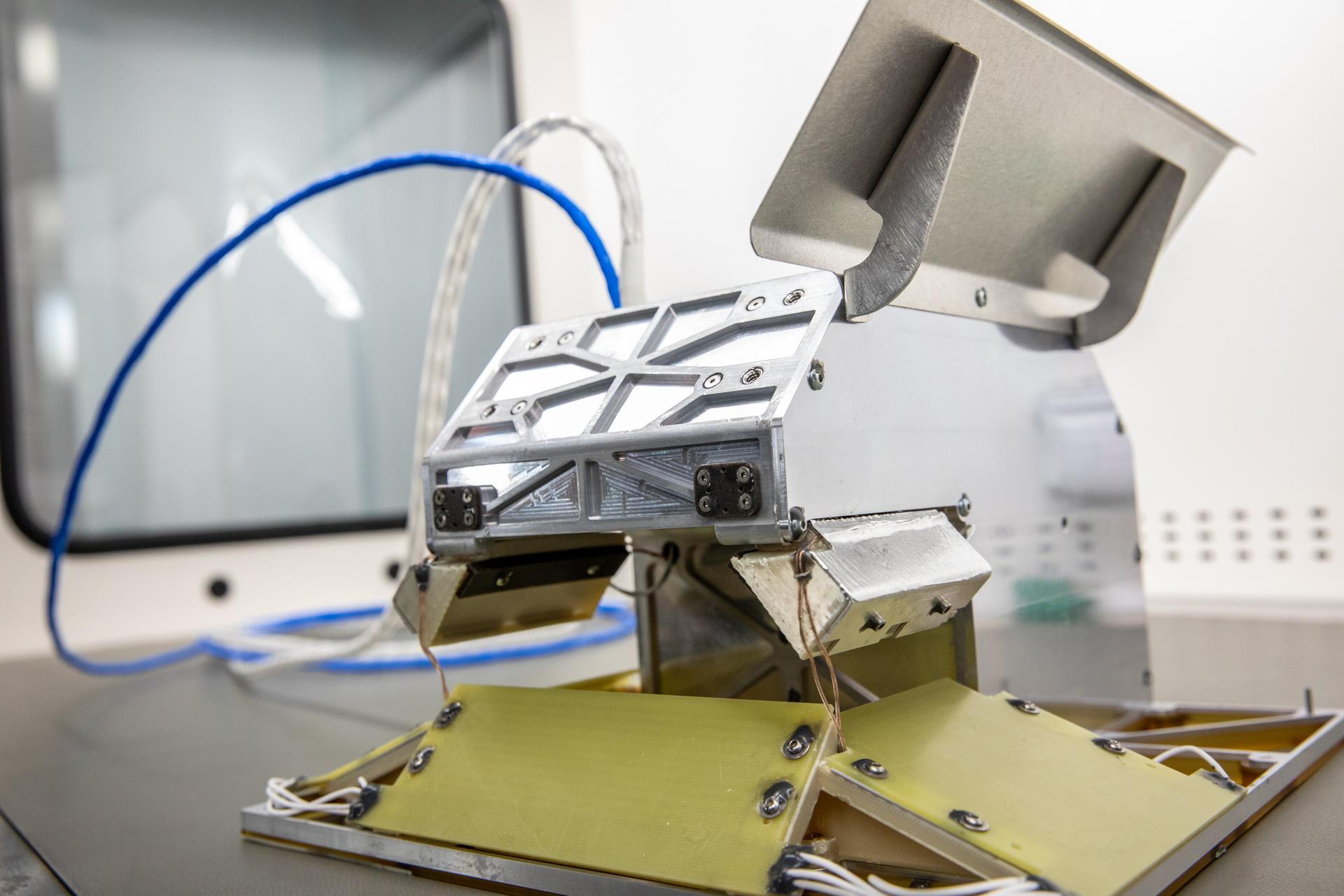

Based on the Electric Curtain concept developed by NASA in 1967, EDS technology has been in development at Kennedy since 2004.

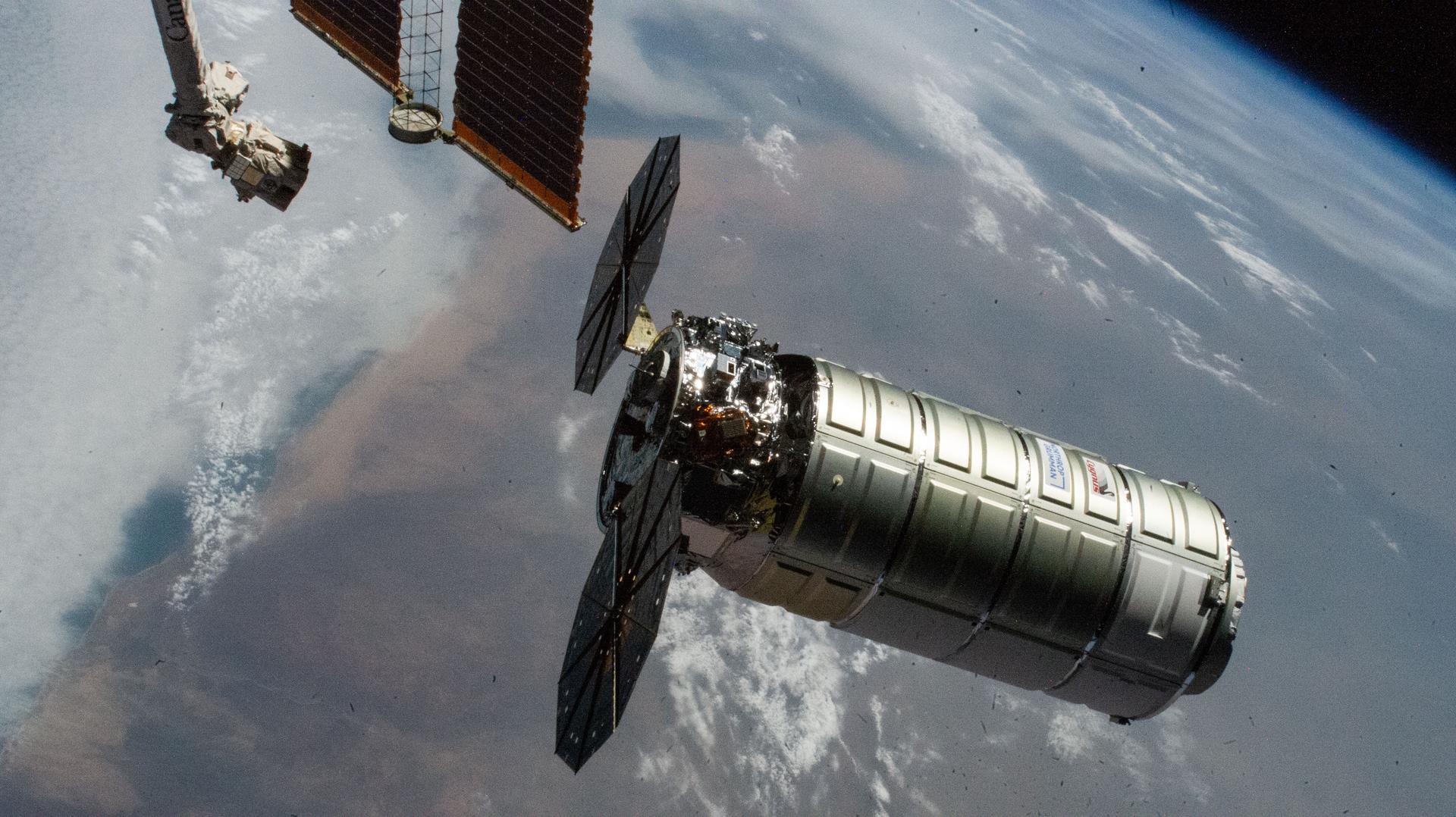

It first made its way to low Earth orbit aboard the NASA Materials International Space Station Experiment 11 mission in 2019. EDS technology was embedded in 12 different panels made of glass, polyimide, and prototype spacesuit fabric and sent to the International Space Station for testing in the vacuum of space.

Before making it to space, EDS had been predominantly tested in vacuum chambers that produced promising results of removing simulants and samples of lunar regolith, collected during NASA’s Apollo missions, from surfaces within a second.

Most recently, as part of Intuitive Machines’ first lunar lander mission, EDS technology was embedded in two lenses of EagleCam, a CubeSat camera system developed by students at Embry Riddle Aeronautical University in Daytona Beach, Florida. Following landing, the EagleCam instrument successfully deployed from Intuitive Machines’ Odysseus lander. The teams at Embry Riddle were unable to acquire images of the lander as they had hoped, but they were able to collect other data sets, including from the EDS technology.

Later this year, another EDS technology demonstration is slated to land on the Moon as part of NASA’s CLPS initiative mission with commercial partner Firefly Aerospace.

“The team has put in a tremendous amount of work and dedication. EDS is considered the leading technology and the best we have for the removal of dust for space applications,” Buhler said. “To fly as a dedicated payload on a mission to the Moon is very exciting.”

According to Buhler, EDS technology could be a first line of defense for establishing an extended human presence on the Moon with future Artemis missions.

From its applications with protecting tools, machinery, and spacesuits, the technology could potentially even help improve day-to-day tasks by being applied to small components like gaskets, seals, and hatches. This could save astronauts the hassle of traveling to the Moon with extra cleaning supplies.

“EDS technology can be used outside of a habitat to help clean surfaces like railings and floors, but it can be used inside as well,” Buhler said. “All of those applications are being evaluated and tested.”

What's Your Reaction?

.jpg?#)