I am Artemis: Jon Carabello

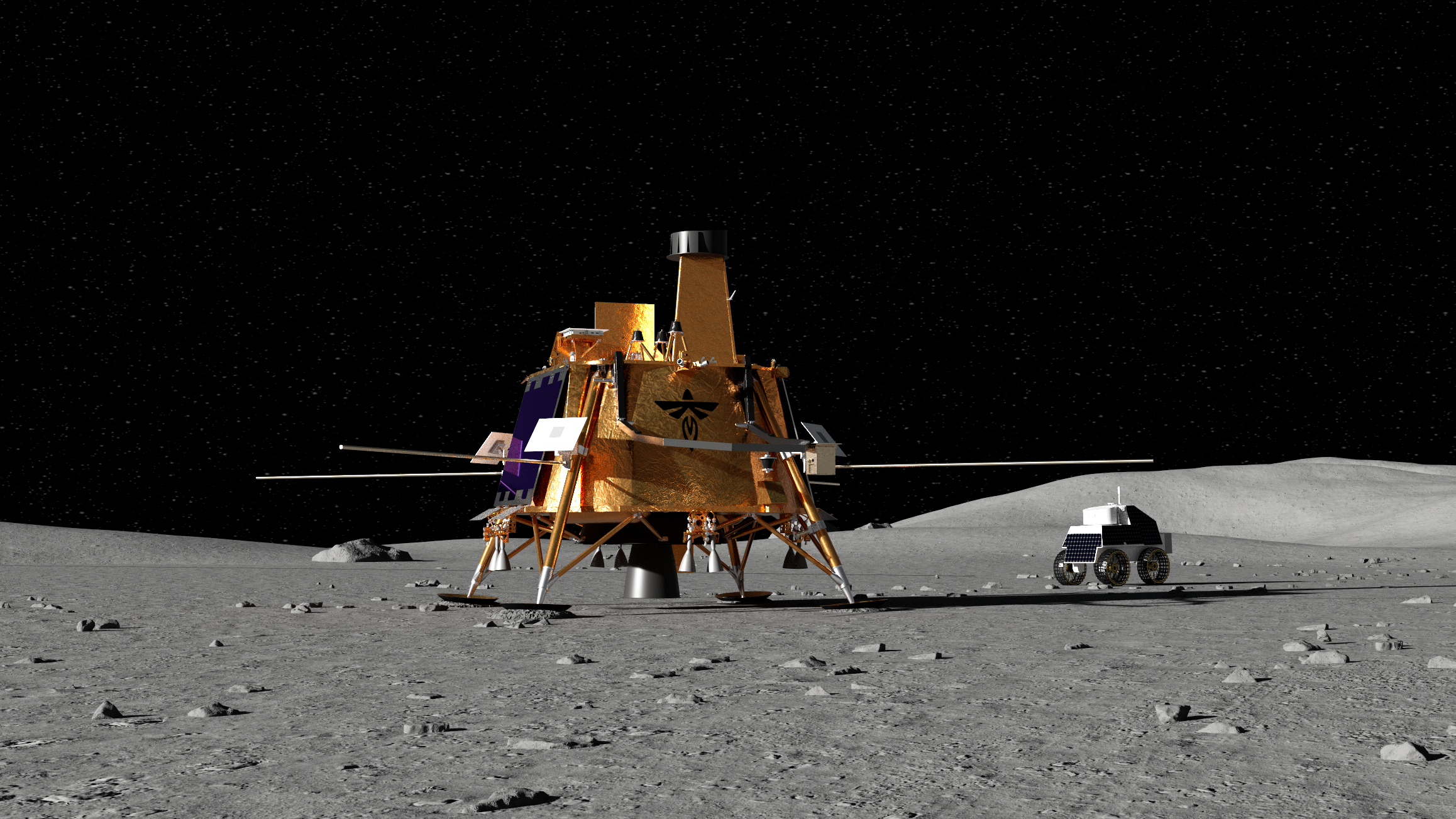

Jon Carabello did not begin his career journey with an eye on space, but when NASA’s Artemis lunar exploration campaign came calling, he was all in. Born, raised, and college-educated in New Hampshire, Carabello has spent his entire professional career at TURBOCAM – a turbomachinery development and manufacturing company – in the southeast corner of […]

Jon Carabello did not begin his career journey with an eye on space, but when NASA’s Artemis lunar exploration campaign came calling, he was all in.

Born, raised, and college-educated in New Hampshire, Carabello has spent his entire professional career at TURBOCAM – a turbomachinery development and manufacturing company – in the southeast corner of the Granite State.

That’s a long way from the southern and western states commonly associated with U.S. human spaceflight activities.

Asked about his early memories of America’s space program, Carabello mentions movies like Apollo 13, and notes that Christa McAulliffe, the teacher-astronaut who died in the 1986 Space Shuttle Challenger accident, taught high school in New Hampshire.

Little did he know that his future employer, a maker of complex machined hardware for a variety of industrial applications, has long been a component supplier to programs including the Space Shuttle and the International Space Station.

There was never much question that Carabello, who started tinkering with engines and other machinery at a young age, would make a career of mechanical engineering. “I like to solve problems – that’s my big thing,” he says.

He learned about TURBOCAM when company representatives made a presentation to his University of New Hampshire engineering class. “That’s how I figured out I knew wanted to work at TURBOCAM and work with 5-axis machining,” he says. “Machining amazes me.”

Five axis machine tools can machine metal blanks from multiple angles to create geometrically complex parts for industrial hardware. TURBOCAM produces 10 core stage main engine turbomachinery components for the RS-25 main engine on NASA’s SLS (Space Launch System) heavy lift exploration rocket. L3Harris Technologies is the prime contractor for the RS-25 engines.

It was his fascination with machining rather than the opportunity to work on rocket engines that drew Carabello to TURBOCAM, where he initially worked on machinery for the oil and gas industry, heating and air conditioning systems, and aerospace.

But then one day, a supervisor asked him to take over the company’s RS-25 portfolio. He remembers the conversion quite clearly.

“It was a Thursday afternoon,” he says. “I was sitting in my office and my manager came in and said, ‘we have somebody leaving and need someone to take over project management and ownership of the RS-25.’ I said, ‘yes’ and he said, ‘you have a call with the program tomorrow.’ That was about five years ago.”

It was a significant change, but Carabello knew the company needed his problem-solving skills on the RS-25 program. “I know how to bring a team together to deliver a quality product. It’s rewarding to know I’m helping return humans to the Moon and paving the way to Mars with the Artemis campaign.”

Self-confidence notwithstanding, Carabello admits to being a bit nervous given that NASA astronauts will be relying on his work. That point was driven home when NASA and L3Harris representatives visited TURBOCAM in the spring of 2024 for a series of presentations on Artemis. The remark that resonated with him the most was by NASA astronaut Dr. Lee Morin, who said the most important part of any human spaceflight mission is bringing astronauts safely home.

“That meant a lot to me,” says Carabello, whose team is responsible for all aspects of TURBOCAM’S RS-25 effort, including quality control, inspection, and resource allocation. He is constantly reminding his team of what’s really at stake for astronauts bound for space: “We’re helping them to return home,” he says.

What's Your Reaction?

.jpg?#)