Carbon Nanotubes and the Search for Life on Other Planets

A NASA-developed material made of carbon nanotubes will enable our search for exoplanets—some of which might be capable of supporting life. Originally developed in 2007 by a team of researchers led by Innovators of the Year John Hagopian and Stephanie Getty at NASA’s Goddard Space Flight Center, this carbon nanotube technology is being refined for […]

A NASA-developed material made of carbon nanotubes will enable our search for exoplanets—some of which might be capable of supporting life. Originally developed in 2007 by a team of researchers led by Innovators of the Year John Hagopian and Stephanie Getty at NASA’s Goddard Space Flight Center, this carbon nanotube technology is being refined for potential use on NASA’s upcoming Habitable Worlds Observatory (HWO)—the first telescope designed specifically to search for signs of life on planets orbiting other stars.

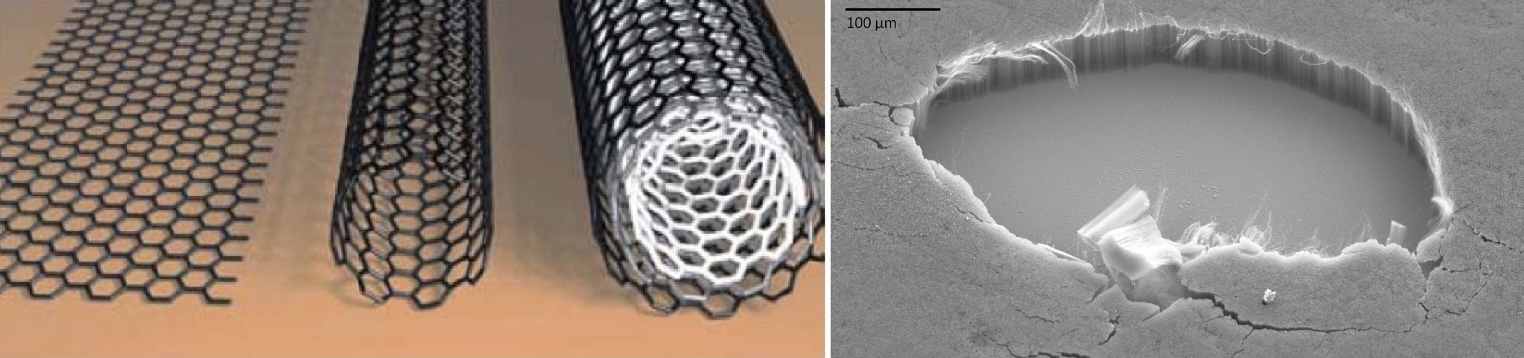

As shown in the figure below, carbon nanotubes look like graphene (a single layer of carbon atoms arranged in a hexagonal lattice) that is rolled into a tube. The super-dark material consists of multiwalled carbon nanotubes (i.e., nested nanotubes) that grow vertically into a “forest.” The carbon nanotubes are 99% empty space so the light entering the material doesn’t get reflected. Instead, the light enters the nanotube forest and jiggles electrons in the hexagonal lattice of carbon atoms, converting the light to heat. The ability of the carbon nanotubes to eliminate almost all light is enabling for NASA’s scientific instruments because stray light limits how sensitive the observations can be. When applied to instrument structures, this material can eliminate much of the stray light and enable new and better observations.

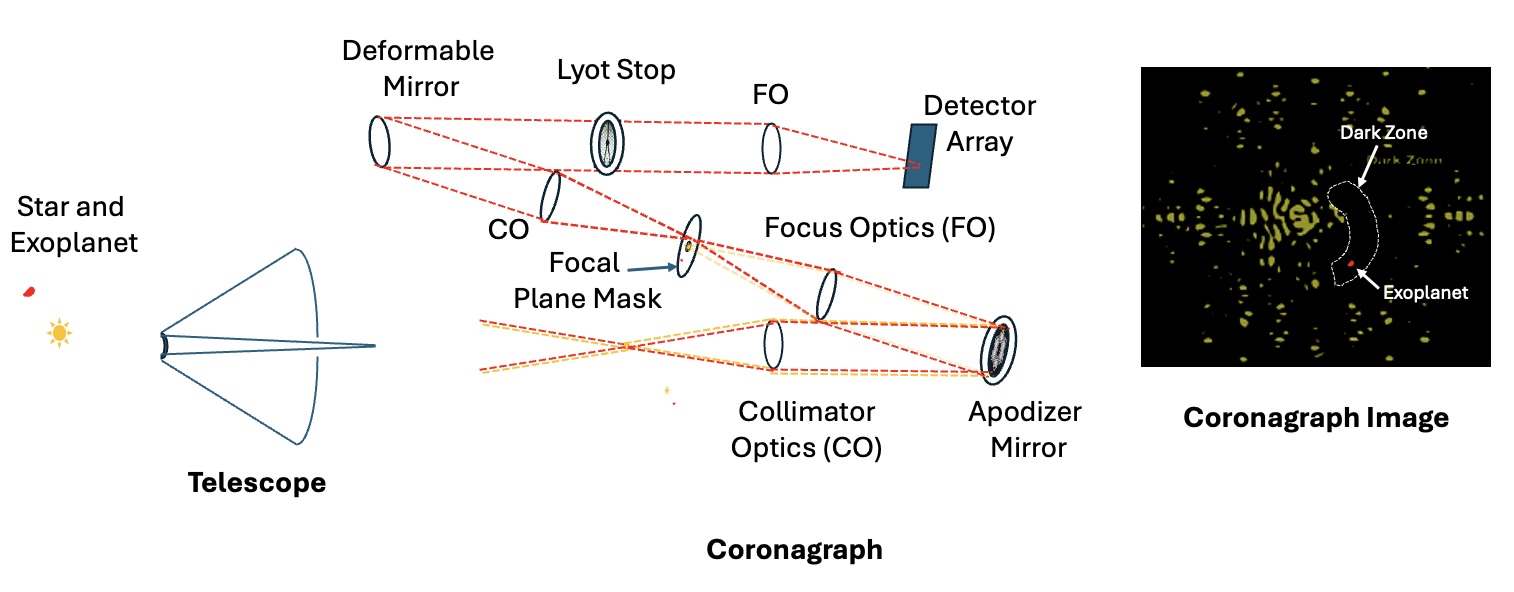

Viewing exoplanets is incredibly difficult; the exoplanets revolve around stars that are 10 billion times brighter than they are. It’s like looking at the Sun and trying to see a dim star next to it in the daytime. Specialized instruments called coronagraphs must be used to block the light from the star to enable these exoplanets to be viewed. The carbon nanotube material is employed in the coronagraph to block as much stray light as possible from entering the instrument’s detector.

The image below depicts a notional telescope and coronagraph imaging an exoplanet. The telescope collects the light from the distant star and exoplanet. The light is then directed to a coronagraph that collimates the beam, making the light rays parallel, and then the beam is reflected off the apodizer mirror, which is used to precisely control the diffraction of light. Carbon nanotubes on the apodizer mirror absorb the stray light that is diffracted off edges of the telescope structures, so it does not contaminate the observations. The light is then focused on the focal plane mask, which blocks the light from the star but allows light from the exoplanet to pass. The light gets collimated again and is then reflected off a deformable mirror to correct distortion in the image. Finally, the light passes through the Lyot Stop, which is also coated with carbon nanotubes to remove the remaining stray light. The beam is then focused onto the detector array, which forms the image.

Even with all these measures some stray light still reaches the detector, but the coronagraph creates a dark zone where only the light coming from the exoplanet can be seen. The final image on the right in the figure below shows the remaining light from the star in yellow and the light from the exoplanet in red in the dark zone.

HWO will use a similar scheme to search for habitable exoplanets. Scientists will analyze the spectrum of light captured by HWO to determine the gases in the atmosphere of the exoplanet. The presence of water vapor, oxygen, and perhaps other gases can indicate if an exoplanet could potentially support life.

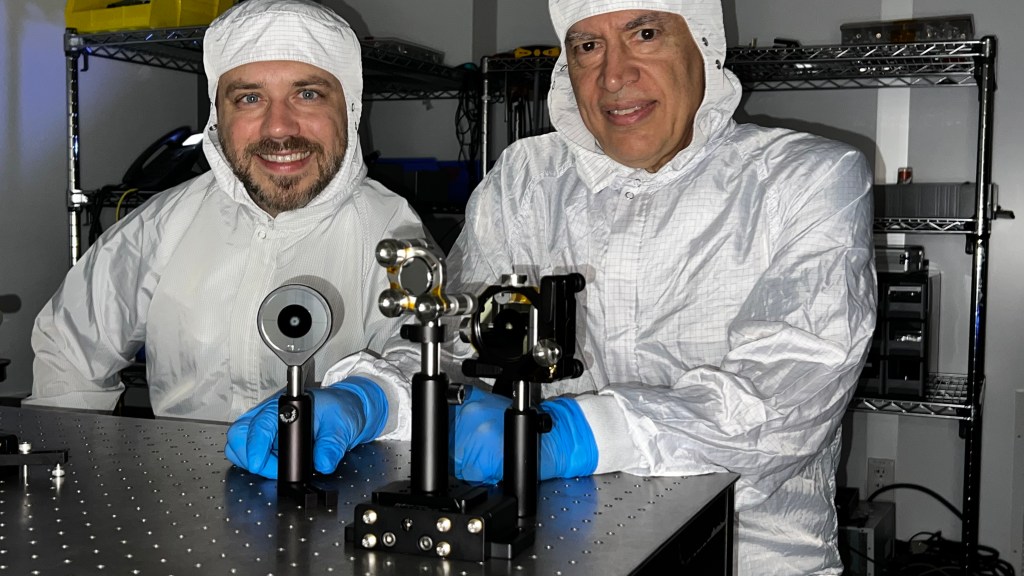

But how do you make a carbon-nanotube-coated apodizer mirror that could be used on the HWO? Hagopian’s company Advanced Nanophotonics, LLC received Small Business Innovation Research (SBIR) funding to address this challenge.

Carbon nanotubes are grown by depositing catalyst seeds onto a substrate and then placing the substrate into a tube-shaped furnace and heating it to 1382 degrees F, which is red hot! Gases containing carbon are then flowed into the heated tube, and at these temperatures the gases are absorbed by the metal catalyst and transform into a solution, similar to how carbon dioxide in soda water fizzes. The carbon nanotubes literally grow out of the substrate into vertically aligned tubes to form a “forest” wherever the catalyst is located.

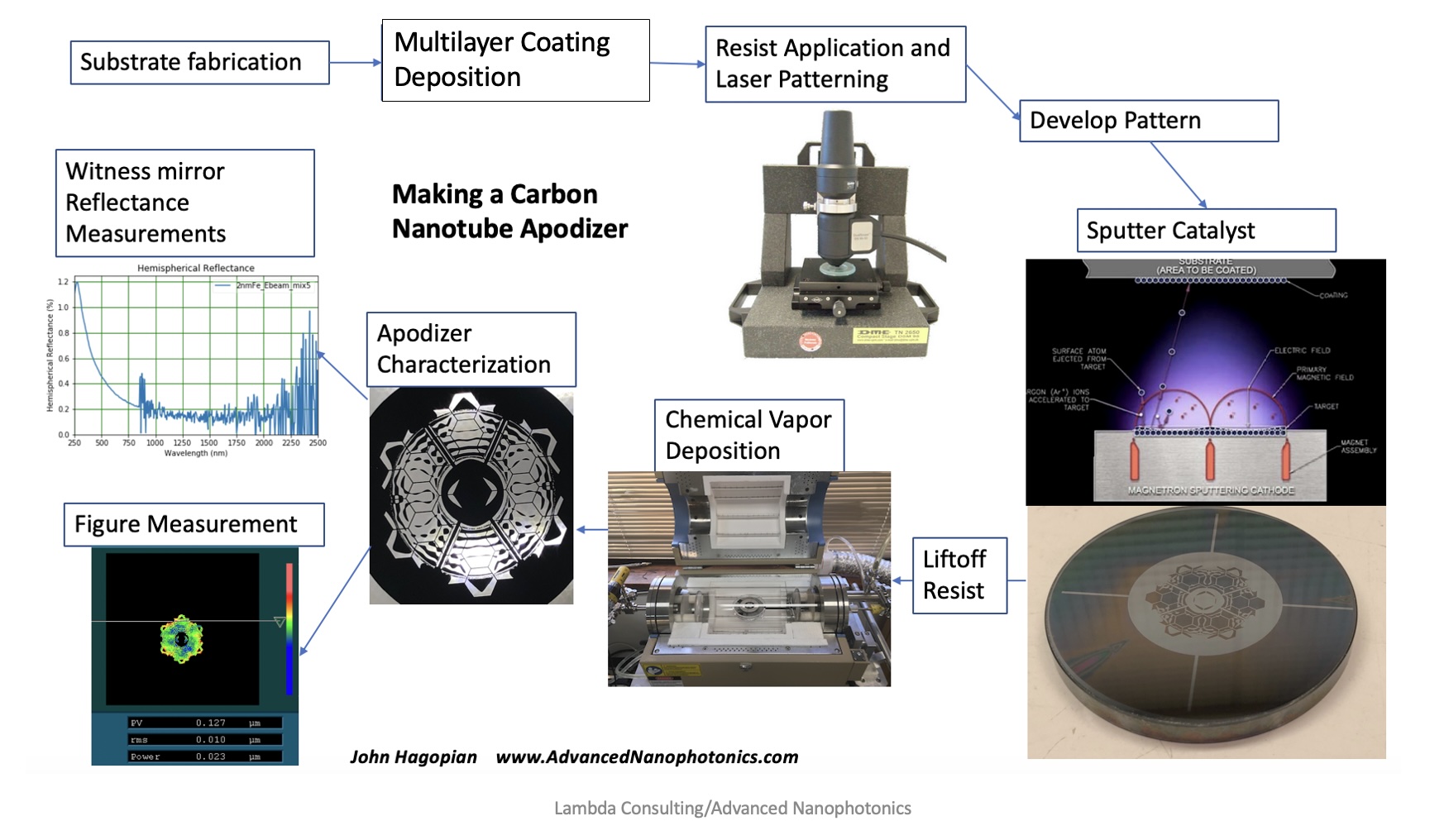

Since the growth of carbon nanotubes on the apodizer mirror must occur only in designated areas where stray light is predicted, the catalyst must be applied only to those areas. The four main challenges that had to be overcome to develop this process were: 1) how to pattern the catalyst precisely, 2) how to get a mirror to survive high temperatures without distorting, 3) how to get a coating to survive high temperatures and still be shiny, and 4) how to get the carbon nanotubes to grow on top of a shiny coating. The Advanced Nanophotonics team refined a multi-step process (see figure below) to address these challenges.

First a silicon mirror substrate is fabricated to serve as the base for the mirror. This material has properties that allow it to survive very high temperatures and remain flat. These 2-inch mirrors are so flat that if one was scaled to the diameter of Earth, the highest mountain would only be 2.5 inches tall!

Next, the mirror is coated with multiple layers of dielectric and metal, which are deposited by knocking atoms off a target and onto the mirror in a process called sputtering. This coating must be reflective to direct the desired photons, but still be able to survive in the hot environment with corrosive gases that is required to grow carbon nanotubes.

Then a material called resist that is sensitive to light is applied to the mirror and a pattern is created in the resist with a laser. The image on the mirror is chemically developed to remove the resist only in the areas illuminated by the laser, creating a pattern where the mirror’s reflecting surface is exposed only where nanotube growth is desired.

The catalyst is then deposited over the entire mirror surface using sputtering to provide the seeds for carbon nanotube growth. A process called liftoff is used to remove the catalyst and the resist that are located where nanotubes growth is not needed. The mirror is then put in a tube furnace and heated to 1380 degrees Fahrenheit while argon, hydrogen, and ethylene gases are flowed through the tube, which allows the chemical vapor deposition of carbon nanotubes where the catalyst has been patterned. The apodizer mirror is cooled and removed from the tube furnace and characterized to make sure it is still flat, reflective where desired, and very black everywhere else.

The Habitable Worlds Observatory will need a coronagraph with an optimized apodizer mirror to effectively view exoplanets and gather their light for evaluation. To make sure NASA has the best chance to succeed in this search for life, the mirror design and nanotube technology are being refined in test beds across the country.

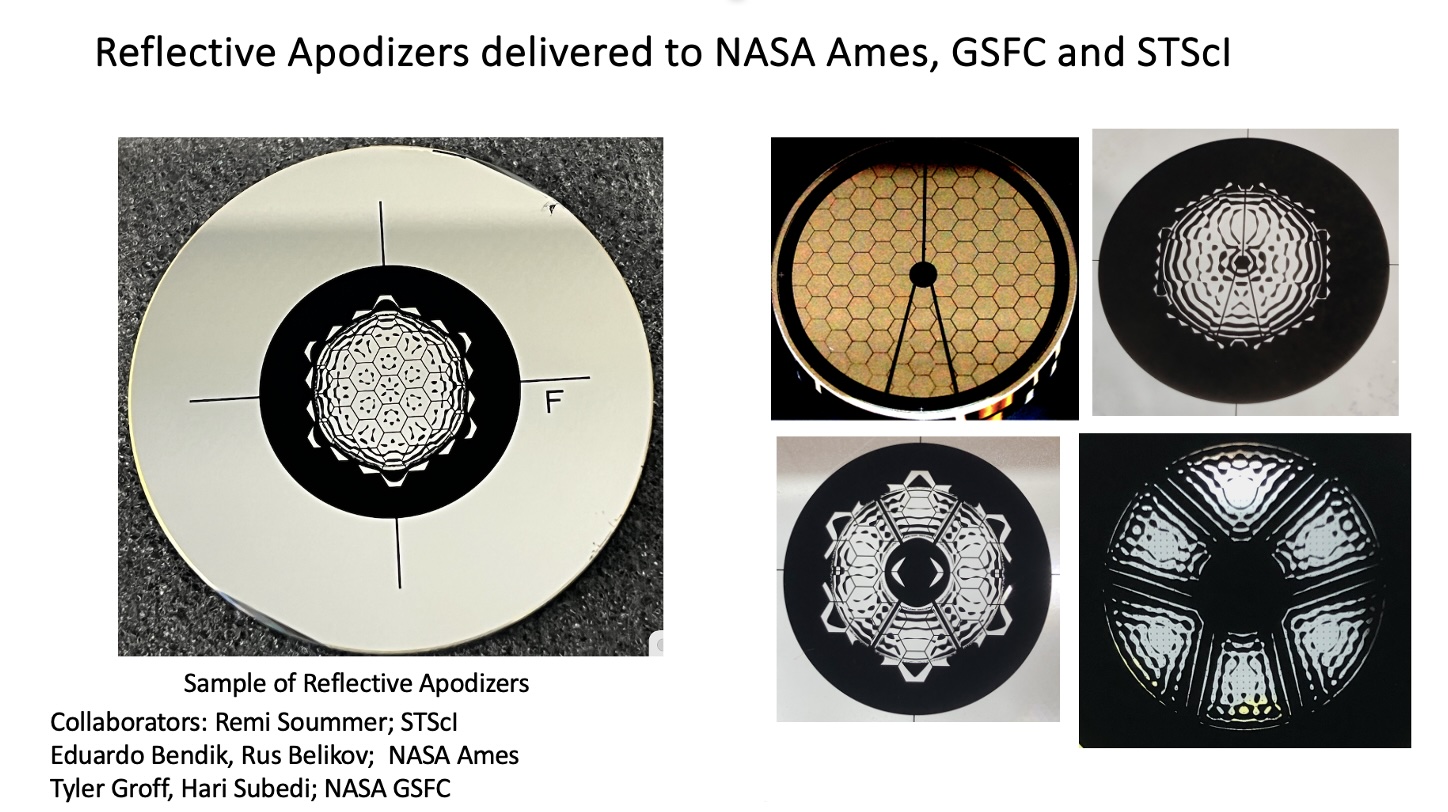

Under the SBIR program, Advanced Nanophotonics, LLC has delivered apodizers and other coronagraph components to researchers including Remi Soummer at the Space Telescope Science Institute, Eduardo Bendek and Rus Belikov at NASA Ames, Tyler Groff at NASA Goddard, and Arielle Bertrou-Cantou and Dmitri Mawet at the California Institute of Technology. These researchers are testing these components and the results of these studies will inform new designs to eventually enable the goal of a telescope with a contrast ratio of 10 billion to 1.

In addition, although the desired contrast ratio cannot be achieved using telescopes on Earth, testing apodizer mirror designs on ground-based telescopes not only facilitates technology development, but helps determine the objects HWO might observe. Using funding from the SBIR program, Advanced Nanophotonics also developed transmissive apodizers for the University of Notre Dame to employ on another instrument—the Gemini Planet Imager (GPI) Upgrade. In this case the carbon nanotubes were patterned and grown on glass that transmits the light from the telescope into the coronagraph. The Gemini telescope is an 8.1-meter telescope located in Chile, high atop a mountain in thin air to allow for better viewing. Dr. Jeffrey Chilcote is leading the effort to upgrade the GPI and install the carbon nanotube patterned apodizers and Lyot Stops in the coronagraph to allow viewing of exoplanets starting next year. Discoveries enabled by GPI may also drive future apodizer designs.

More recently, the company was awarded a Phase II SBIR contract to develop next-generation apodizers and other carbon nanotube-based components for the test beds of existing collaborators and new partners at the University of Arizona and the University of California Santa Clara.

As a result of this SBIR-funded technology effort, Advanced Nanophotonics has collaborated with NASA Scientists to develop a variety of other applications for this nanotube technology.

A special carbon nanotube coating developed by Advanced Nanophotonics was used on the recently launched NASA Ocean Color Instrument onboard the Plankton, Aerosol, Cloud, ocean Ecosystem (PACE) mission that is observing both the atmosphere and phytoplankton in the ocean, which are key to the health of our planet. A carbon nanotube coating that is only a quarter of the thickness of a human hair was applied around the entrance slit of the instrument. This coating absorbs 99.5% of light in the visible to infrared and prevents stray light from reflecting into the instrument to enable more accurate measurements. Hagopian’s team is also collaborating with the Laser Interferometer Space Antenna (LISA) team to apply the technology to mitigate stray light in the European Space Agency’s space-based gravity wave mission.

They are also working to develop carbon nanotubes for use as electron beam emitters for a project sponsored by the NASA Planetary Instrument Concepts for the Advancement of Solar System Observations (PICASSO) Program. Led by Lucy Lim at NASA Goddard, this project aims to develop an instrument to probe asteroid and comet constituents in space.

In addition, Advanced Nanophotonics worked with researcher Larry Hess at NASA Goddard’s Detector Systems Branch and Jing Li at the NASA Ames Research Center to develop a breathalyzer to screen for Covid-19 using carbon nanotube technology. The electron mobility in a carbon nanotube network enables high sensitivity to gases in exhaled breath that are associated with disease.

This carbon nanotube-based technology is paying dividends both in space, as we continue our search for life, and here on Earth.

For additional details, see the entry for this project on NASA TechPort.

PROJECT LEAD

John Hagopian (Advanced Nanophotonics, LLC)

SPONSORING ORGANIZATION

SMD-funded SBIR project

Share

Details

Related Terms

What's Your Reaction?

.jpg?#)