BioNutrients Flight Experiments

On-demand nutrient production system for long-duration missions When astronauts embark on long space missions, they’ll need to grow their own food because pre-packaged meals from Earth lose their nutritional value over time. The BioNutrients project at Ames Research Center’s Space Biosciences Division has solved this problem by using genetic engineering to create microbially-based food that can […]

On-demand nutrient production system for long-duration missions

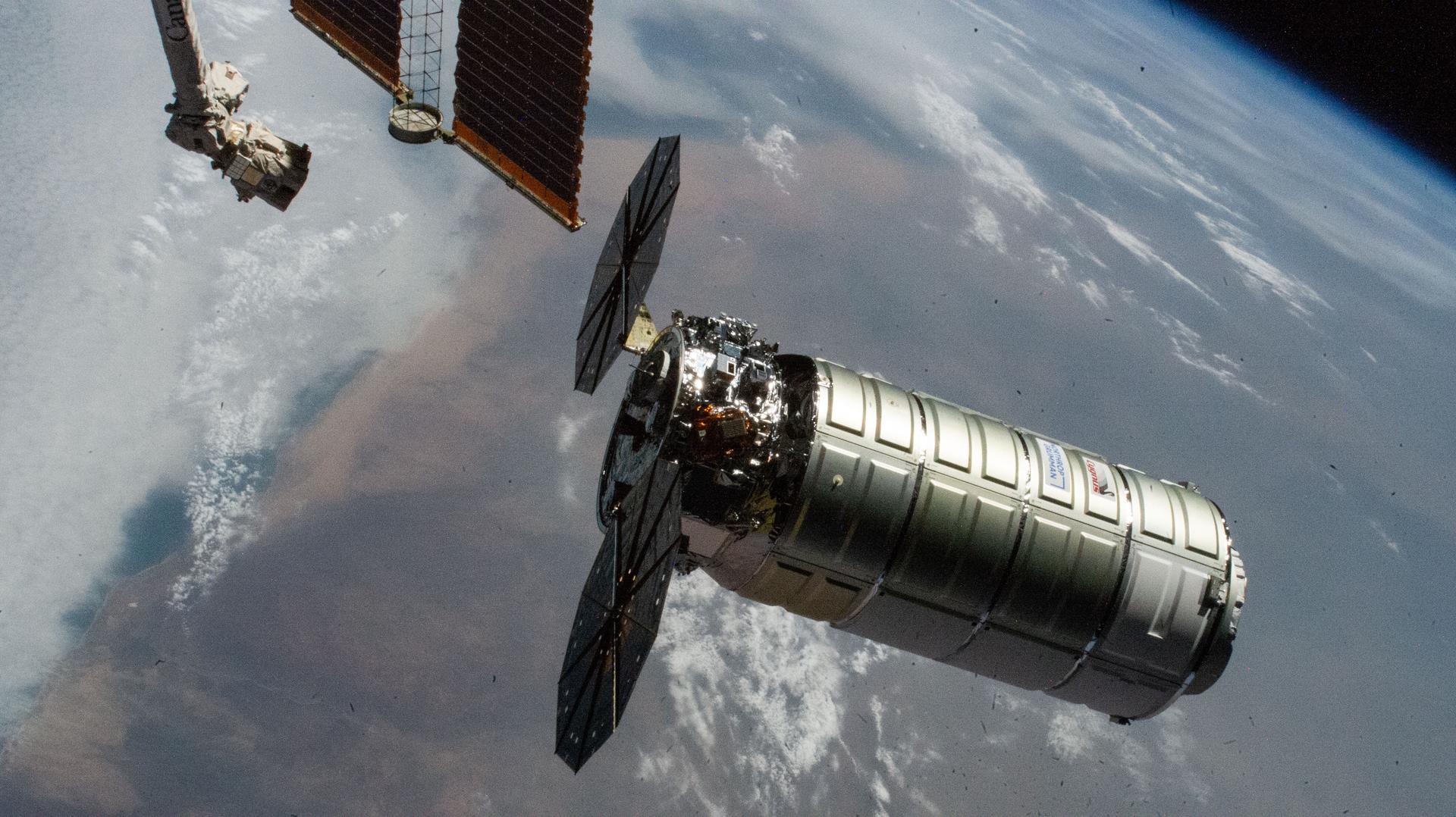

When astronauts embark on long space missions, they’ll need to grow their own food because pre-packaged meals from Earth lose their nutritional value over time. The BioNutrients project at Ames Research Center’s Space Biosciences Division has solved this problem by using genetic engineering to create microbially-based food that can produce nutrients and compounds, such as medicines, with minimal resources. The process involves storing dried microbes and food-grade media in small bioreactors, which can be rehydrated and grown years later. The project has already produced carotenoids for antioxidants, follistatin for muscle loss, and yogurt and kefir for a healthy gut biome.

Main Findings: Two different engineered baker’s yeasts were cultured in the BioNutrients-1 (BN-1) Gen-0 bioreactors, producing beta-carotene and zeaxanthin, and their ambient shelf life on the International Space Station (ISS) has now been demonstrated out to 3.9 years. Four additional organism types and products were flown on BioNutrients-2 (BN-2), demonstrating the production of carotenoids, follistatin, yogurt, and kefir products in the Gen-1 bioreactors which have a 91% reduced mass and a flat pack design. The shelf life of yeast-based products is expected to meet 5 years at ambient storage conditions. Analysis of yogurt and kefir is underway.

Impact: BN-1 and BN-2 successes pave the way for further biomanufacturing processes that will ensure the safe consumption of essential nutrients and compounds for long-duration space missions.

Co-Investigators: John Hogan and Frances Donovan

Team: Ball, N., Sharif, S., Downing, S., Gresser, A., Hami, R., Oscar, R., Hindupur, A., Hiromi, K., Kostakis, A., Levri, J., Murikami, M., Settles, A.M., Sims, K., Villanueva, A., Vu, S.

What's Your Reaction?

.jpg?#)