2024 Invention of the Year Winner – Thrust Chamber Liner and Fabrication Method

NASA Marshall Space Flight Center: A thrust chamber assembly (TCA) is the critical and central component in a rocket engine that provides thrust to propel a launch vehicle into space. Since the 1960s, while small improvements in TCA performance have been made, little has been done to reduce weight, improve development timelines, and reduce manufacturing cost. […]

4 min read

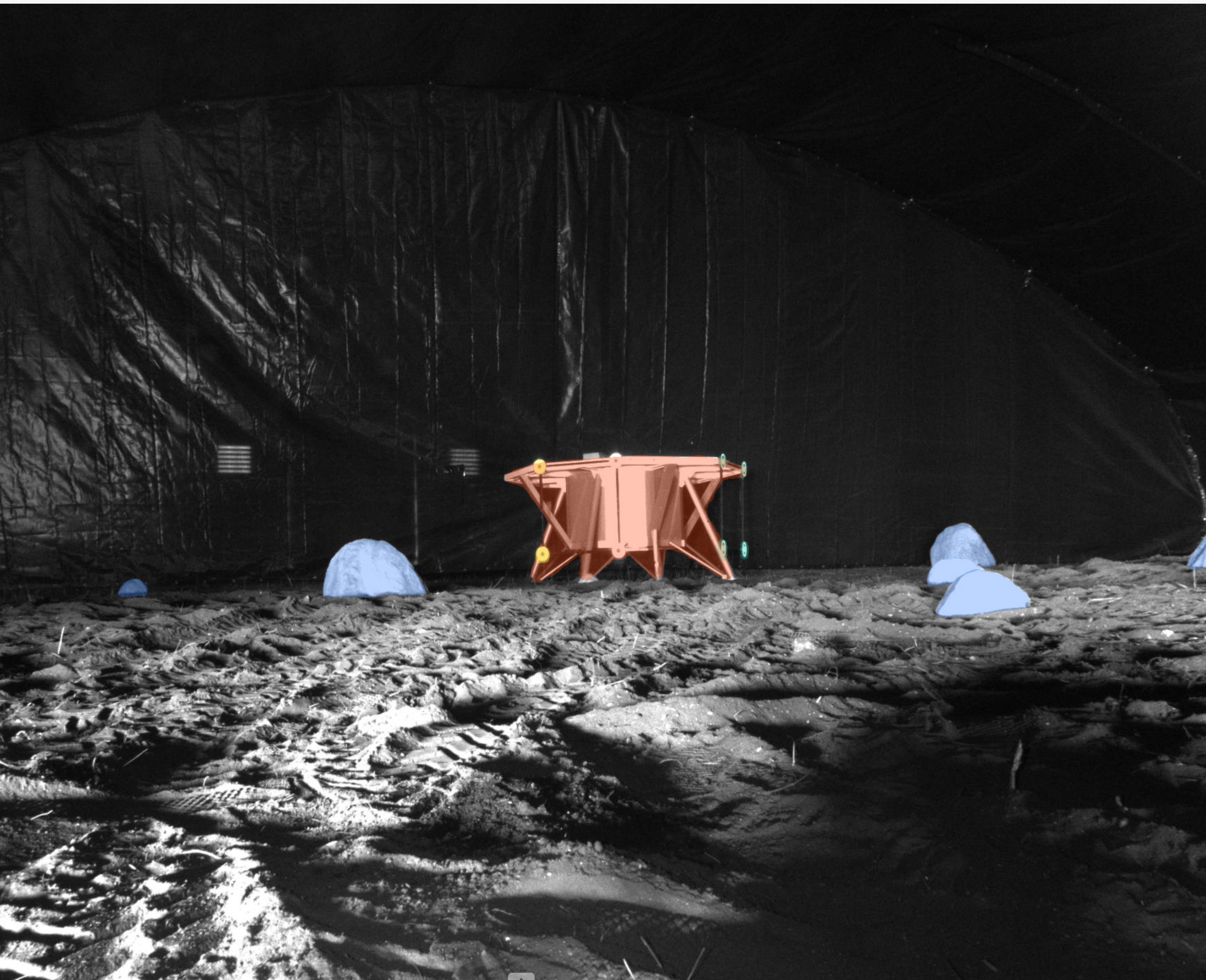

Preparations for Next Moonwalk Simulations Underway (and Underwater)

NASA Marshall Space Flight Center: A thrust chamber assembly (TCA) is the critical and central component in a rocket engine that provides thrust to propel a launch vehicle into space. Since the 1960s, while small improvements in TCA performance have been made, little has been done to reduce weight, improve development timelines, and reduce manufacturing cost. This invention makes dramatic improvements in all three areas.

This Thrust Chamber Liner and Fabrication Method technology eliminates complex, bolted joints by using 3D printing and large-scale additive manufacturing (AM) to fabricate a one-piece TCA. This creates a combined combustion chamber and nozzle. A novel composite overwrap provides support with an overall mass reduction of >40%. The TCA is the heaviest component on the rocket engine, so every pound eliminated allows for additional payload. The benefits include significantly better performance of launch vehicles, consolidation of parts, and a simplified fabrication that reduces cost and lead time.

A liquid rocket engine provides thrust through the injection of a fuel and oxidizer into a combustion chamber then expanding the hot gases through a nozzle. The engine’s core component is the TCA, which comprises an injector, a combustion chamber, and a nozzle. To prevent the TCA’s wall material from reaching melting temperatures, a regenerative cooling system is employed. Small internal channels circulate either fuel or oxidizer as a coolant before it’s injected into the combustion chamber for the combustion process.

The TCA must withstand a wide range of challenges, including extreme temperatures (from cryogenic temperatures below -290 °F and up to +6,000°F), high pressures (up to 6,000 psi), demanding duty cycles that impact fatigue life, engine dynamics, and the reactive thrust loads. This necessitates the use of a variety of materials and involves intricate manufacturing and joining processes while maintaining exceptionally tight tolerances. The walls can be as thin as a few sheets of paper, measuring approximately 0.02 inch, increasing the complexity of the technological challenge.

The design and construction of the combined combustion chamber and nozzle has several novel features: (1) A NASA-developed alloy, Copper-Chrome-Niobium (GRCop-42) was matured for the combustion chamber resulting in a 45% increase in wall temperatures. (2) The integral channel design supports effective cooling, manifolds, and a range of features that facilitate an integrated coupled nozzle and composite overwrap. (3) The chamber and its internal structures are produced using a NASA-developed (and later commercialized) process known as laser powder bed fusion (L-PBF). This uses minimal exterior material, allowing the composite overwrap to effectively contain the high pressure and various engine loads. (4) Stock material and integral features build the chamber nozzle onto the aft end using a different alloy, optimizing the overall strength-to-weight ratio. (5) Traditionally, AM requires a build plate onto which parts are fabricated, but this innovation can use the chamber itself as the build plate. (6) A large-scale AM process called laser powder directed energy deposition (LP-DED) was developed with a new NASA alloy for hydrogen environments, called NASA HR-1 (HR = hydrogen resistant). The AM employed to integrate the chamber and nozzle involves the use of two distinct AM processes and alloys, using GRCop-42 for the chamber and NASA HR-1 for the nozzle.

A composite overwrap significantly reduces weight and provides adequate strength to sustain required pressures and loads. Various filament winding techniques and fiber orientations, guided by modeling simulations effectively counteract the (barrel) static pressure, startup, and shutdown loads, thrust, and gimbal loads. The unique locking features designed into the chamber include turn-around regions (referred to as “humps”) to eliminate complex tooling.

Traditional TCA design incorporates multiple manifolds, adding unnecessary weight and bolted or welded joints. These joints necessitate exceedingly tight tolerances, polished surface finishes, and intricate sealing mechanisms to prevent leakage. Maintaining precise concentricity among the components and ancillary features, such as shear-lips to avoid hot gas circulation and joint separation, is imperative. The risk of potential leakage can lead to the catastrophic failure of the engine or the entire vehicle. The tragic explosion of the Space Shuttle Challenger serves as a stark reminder of how joint failure, albeit in a solid rocket motor in that case, can have dire consequences. By contrast, this design eliminates these vulnerabilities by employing integrated AM processes to create a one-piece TCA, dramatically improving safety and efficiency.

Thrust Chamber Liner Team

- Paul R. Gradl

- Christopher Stephen Protz

- Cory Ryan Medina

- Justin R. Jackson

- Omar Roberto Mireles

- Sandra Elam Greene

- William C. C. Brandsmeier

Share

Details

Related Terms

What's Your Reaction?

.jpg?#)